China Injection Molding Sourcing: A Complete Guide

So, the big meeting just wrapped up. your new product has been approved, time is pressing, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. Savings can be substantial. But your mind is already racing. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold company can be a calculated project. It’s a project, just like any other. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Forget the horror stories. Let’s walk through a real-world playbook for getting it right.

First Things First: Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Start with your 3D design files. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. Here you specify what 3D can’t show. Think tolerances, material grades, finish specs, and any feature-critical notes. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Don’t just say “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

Now that your RFQ is pristine. who gets your RFQ? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Consider using a sourcing agent. Yes, they take a cut. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. On your first run, this is like insurance. It’s schedule protection.

Another classic method? Trade shows. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. And don’t forget the oldest trick in the book: referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. Some prices will undercut logic, others will shock you. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How do you do that? It involves both metrics and gut feel.

Begin with responsiveness. Do they respond quickly and clearly? Can they handle detailed English exchanges? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

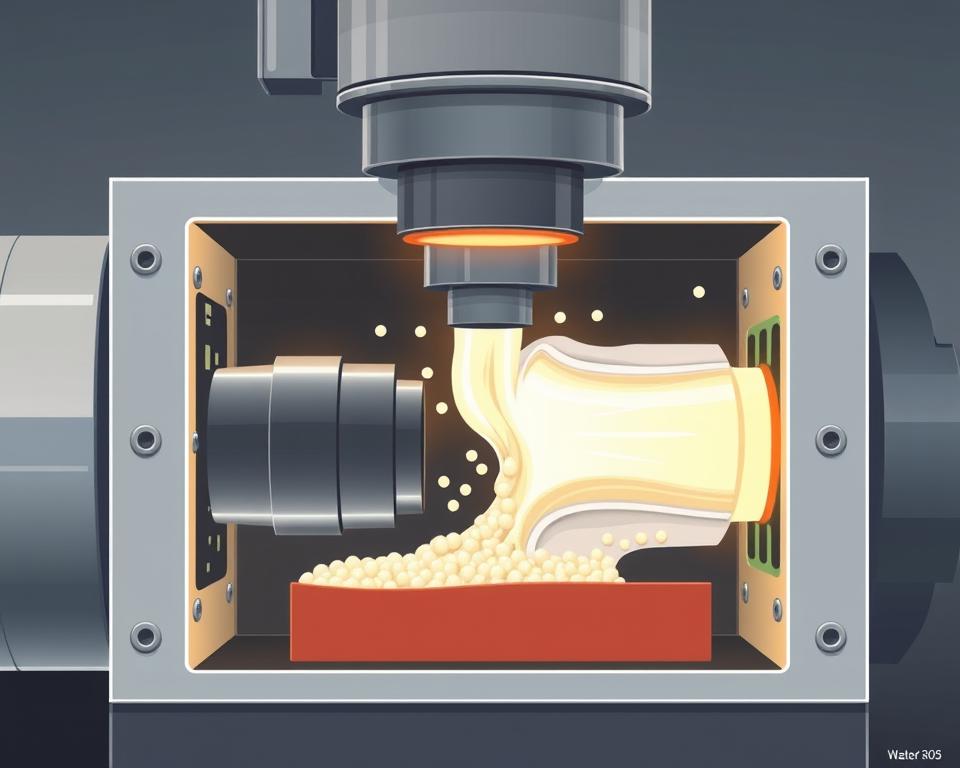

Initially, expect a DFM report. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A thorough DFM is a sign of a professional operation. It’s a collaboration. Together, you tweak the design for best manufacturability.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. It’s your first real test.

T1 parts usually require adjustments. It’s par for the course. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. You may repeat this cycle a few times. Build buffer time for sample iterations.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This step saves you from a container of rejects.

Don’t forget shipping details. Understand the shipping terms, or Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’ve got this.